BIMAL ALUMINIUMS is one of the prominent Dairy Equipment Manufacturers. We are dedicated to facilitating the country by delivering world-class dairy machinery. Since milk is one of the best immunity boosters for all ages, it is essential to maintain its nutritional value. Keeping this perspective in mind, we bring a complete dairy equipment solution that is dealing with treating raw milk. This Dairy equipment is pasteurized and can make all kinds of milk-based products such as curd, ghee, butter, yogurt, lassi, Misti Dohi, flavored milk, paneer, cheese, various types of milk beverages, and ice cream processing as well.

In every state of milk processing from reception, we give priority to clarification, homogenization, and heat-based pasteurization for finishing product packaging and storage. Our dairy equipment solution is designed to meet every specification, keep safety, care, and also balance the natural and valuable nutrients in the milk that is essential for a good and healthy diet for an infant as well as elderly people.

As a Dairy Equipment Manufacturer, we emphasize on a technology-driven approach and deliver the most innovative machinery and dairy equipment which is ultra-advanced with the newest technology.

1. Machine work long hours a day that increases the dairy farm activities at the large scale

2. Produces good and hygienic dairy products with their natural nutritional value

3. Less maintenance requires i.e. machines easy to clean with fewer efforts

4. Takes less time and space, and multiple benefits to the dairy business

5. Keeps maintain high nutrient content that improves health benefits

6. Reduces the farms’ workload and workers' dependency

7. Keep farms clean, safe and healthy

At BIMAL ALUMINIUMS, we follow the most stringent quality procedure to meet the requirement of delivering high-quality dairy equipment. Sourcing high-rated quality basic materials we design highly durable and customized equipment that caters to the industrial specifications set by Indian standard organization. Moreover, this equipment is very affordable from the leading market rates.

|

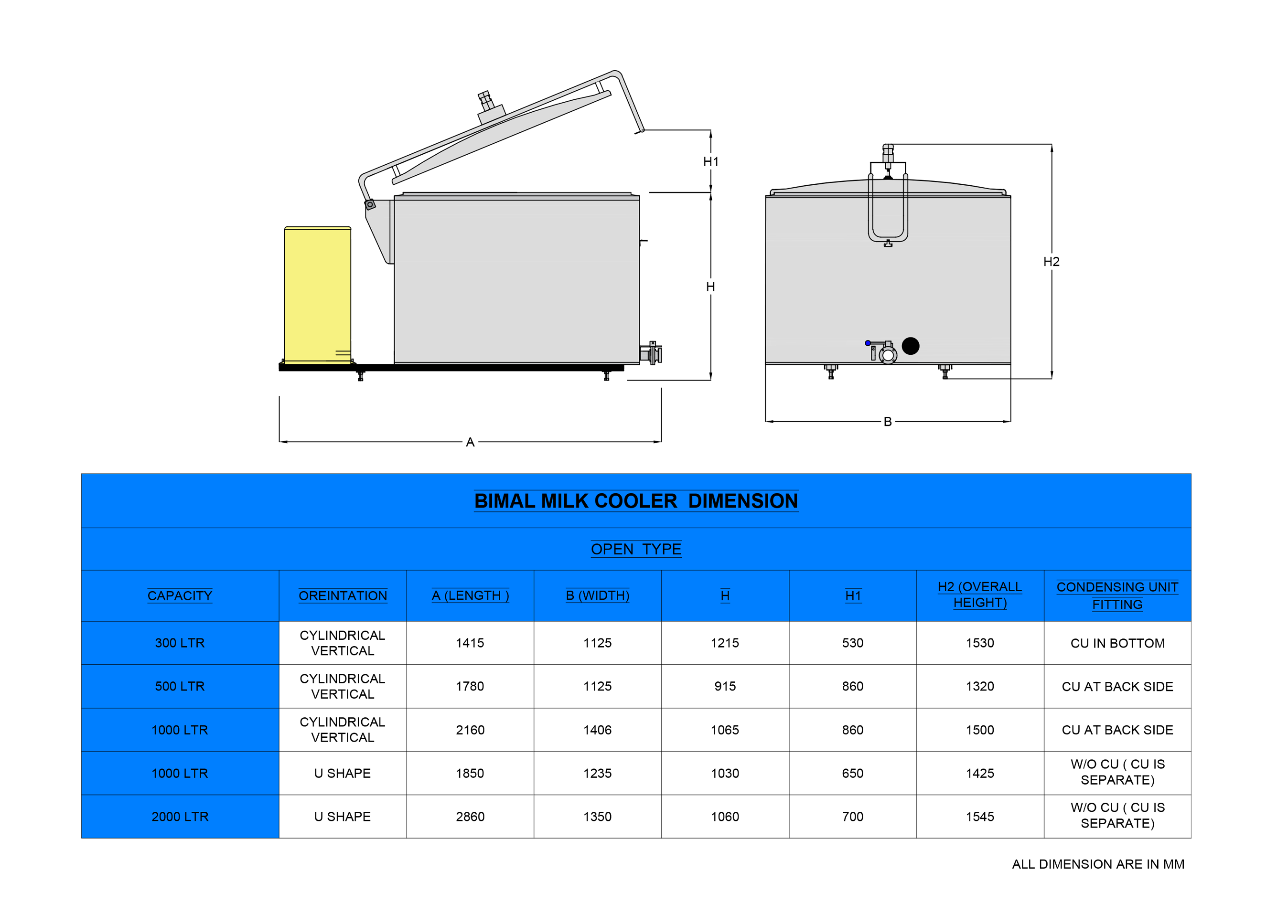

Technical Specifications: Open Type BMC |

||||

|

Particulars |

300 LTR |

500 LTR |

1000 LTR |

2000 LTR |

|

Model/Type of tank |

BI 300L CV |

BI 500L CV |

BI 1000L CV |

BI 2000L USH |

|

Orientation |

CYLINDRICAL VERTICAL |

CYLINDRICAL VERTICAL |

CYLINDRICAL VERTICAL |

SEMI CYLINDRICAL / U SHAPE |

|

Gross capacity |

330 LTR |

550 LTR |

1100 LTR |

2200 LTR |

|

Thermo plate |

Laser Welded Pillow Plate |

Laser Welded Pillow Plate |

Laser Welded Pillow Plate |

Laser Welded Pillow Plate |

|

Construction material |

AISI 304 SS |

AISI 304 SS |

AISI 304 SS |

AISI 304 SS |

|

Milk measuring facility |

S.S DIP STICK |

S.S DIP STICK |

S.S DIP STICK |

S.S DIP STICK |

|

Agitator rpm/number |

30 RPM / 1no |

30 RPM / 1no. |

30 RPM / 1no. |

30 RPM / 1no. |

|

Make of compressor |

Emerson |

Emerson |

Emerson |

Emerson |

|

No. of condensing Unit |

one |

one |

one |

Two |

|

Type of refrigerant |

R-22 / R404 A |

R-22 / R404 A |

R-22 / R404 A |

R-22 / R404 A |

|

Insulation |

Cfc free , polyurethane puff |

Cfc free , polyurethane puff |

Cfc free , polyurethane puff |

Cfc free , polyurethane puff |

|

ISO Standard Follow |

As per ISO 5708 2AII Latest Version |

As per ISO 5708 2AII Latest Version |

As per ISO 5708 2AII Latest Version |

As per ISO 5708 2AII Latest Version |

|

Power requirement |

Single |

Single/Three phase |

Single/Three phase |

Single/Three phase |